What is a PLM project ?

The digital transformation of industry is an approach that uses cutting-edge technologies to reinvent products & services in order to accelerate operational efficiency and business growth.

PLM is a business strategy designed to create, manage and share all information about the definition, manufacturing, maintenance and recycling of an industrial product throughout its life cycle using a Technical Information System. A PLM project is in this context a commitment to deliver a solution (IT application) that meets these challenges.

A PLM project is inherently transversal by nature, distributed across the customer’s different departments, and carries the genetics of its products, its know-how and its market offering.

A PLM project is usually based on a tripartite organization between a customer (the future user of the solution), a software editor (the solution creator and vendor) and an integrating service company (which will complete the project within the conditions of time, quality and cost set by the customer).

A PLM project can target companies with few but extremely complex products, with bills of materials with several thousand components (e.g. aeronautics, automotive, railways) as well as companies with simpler products, with smaller bill of material but with hundreds of variants (cosmetics, food processing), not to mention new sectors such as civil engineering or financial services.

Historically developed for large manufacturing companies, a PLM project is now also aimed at small and medium-sized enterprises: a project structuring, sizing, and timing executed in lean mode, without denying certain project management fundamentals, must adhere to the customer’s organizations and capabilities.

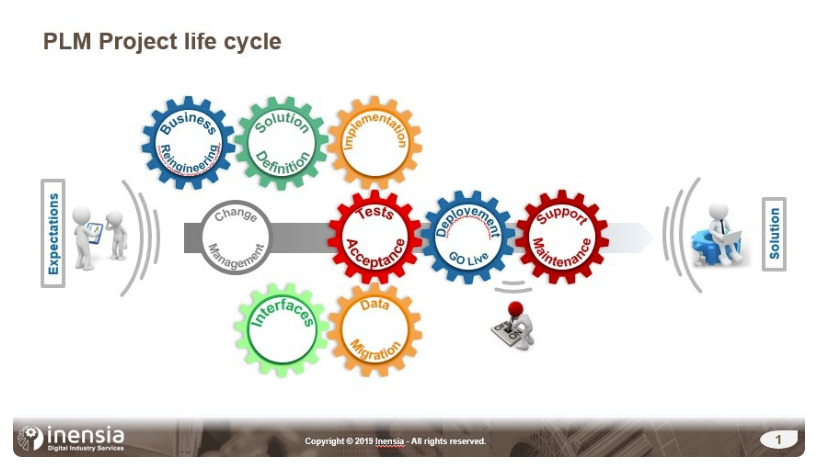

The development (or life cycle) of a PLM project can be seen in the form of an orderly coordination between different phases, each phase having a specific objective, an organization of its activities, an RACI and deliverables.

The Industry PLM Project Manager vs. the Service Integrator PLM Project Manager

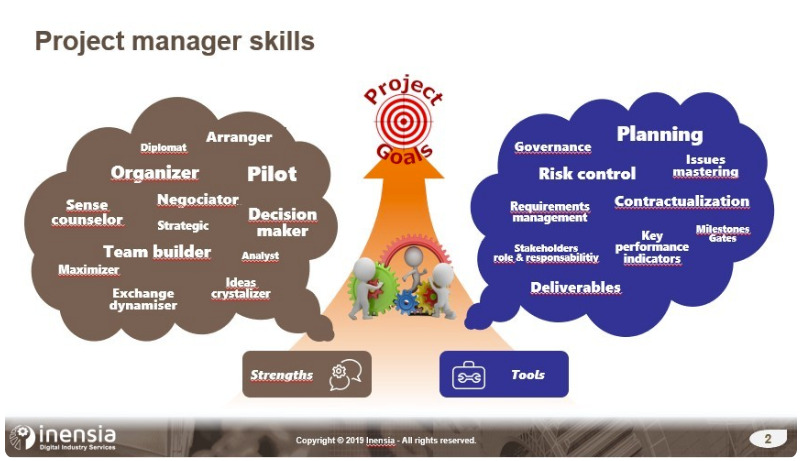

A PLM project is first and foremost project in the basic sense of the term, for which the project manager will have to implement management methodologies framework (such as ISO, PMI, Prince2), combining governance, requirements management and risk management.

On the industry side, the PLM project manager must master the business and culture of his company. He knows what is important to everyone, knows the products, the internal vocabulary, the company organization and the processes that govern its operation.

He is not an IT specialist, but rather someone functionally skilled in the customers business.

His long and broad professional experience in the same industrial sector gives him credibility among many necessary qualities.

He must be a senior manager, close to the executive management. In practice, he has already been responsible for cross-functional projects. He is able to manage teams from different departments, with sometimes conflicting objectives. This requires a proven track record in communication and persuasion. These qualities are useful in imposing product life cycle management in the company.

Quite frequently, the PLM industrial project manager is also the one who initiated the project.

On the integration services side, the PLM project manager is accountable for customizing and deploying an IT solution.

He must have some knowledge of the technologies (software solutions) associated with his business, but he is not required to know perfectly a specific tool. However, he must fully understand and control all the steps involved in the development and integration of a PLM solution (as broken down below) as well as related topics and particularly technical issues such as data migration or interfacing with third-party applications.

The PLM integration services project manager must also be familiar with the industry practices, the processes of designing, developping and industrializing new products and have a strong business sensitivity that can help him evaluate at best balance between the cost, relevance and deadlines. He must be able to evaluate and weigh the customer’s change requests that can be included in the original plan and fixed budget without financial compensation.

The integrator PLM project manager is the bridge and responsible to conciliate between business needs and the technical solution.

Whether client-side or integrator-side the success of a project obviously also relies on the social skills of the project manager.

Moving towards a single, simple goal

Regardless of working in the industry or for a service company, the focal point to never lose sight of is that a PLM project must serve the business of the company by adding value. If the PLM deployed does not meet the challenges experienced by the operational business units, it will be misused or even not used at all, and bypass solutions will be implemented.

A few thoughts and observations feeding the foundation of a project’s success:

- A PLM project must be a business project before it can be a digital solution integration project

- Systematically reusing and simply digitalising existing old processes within the PLM is a mistake. An assessment and re-engineering of processes (simplification, elimination of redundancies, removal of unnecessary tasks) is essential, focusing on what they should be in the future in the light of ever evolving technologies and changing business.

- An efficient project management is not sufficient. It must be backed by a strong sponsorship which can participate in setting the guidelines, ambitions, trajectory and evolutions of the project and ensure if required the necessary arbitration between the client, integrator and editor

- A PLM project must be carried out in stages and not seek to implement 100% of the scope from the start. Beginning with the main core functions, and making sure they are used, is paramount to success.

- A judicious break-down of the project into progressive batches and small bets combined with an implementation following the Agile methodology will facilitate small victories, in contrast to the large batches frequently doomed to fail.

- The performance of an Agile approach, the implementation methodology that is mostly used today, is not just about the speed and frequency of deployments; a real measure of the value provided to the business over the deliveries must remain a key indicator.

- An approach pushing the Out Of The Box to the extreme may hinder the adoption of the solution by its future users. Of course, the features offered by the solution must be built on, without prohibiting some specific developments that are necessary and reduced to only value-added features. The key is to respect the rules of the software publisher to ensure that the solution can be maintained and that its cost of ownership remain under control.

- The PLM deployed must have the capacity to evolve further functionally and technically. If the PLM solution cannot keep up or painted itself in a corner when new needs or contexts arise, its deployment will be limited and ultimately lead to alternative replacement solutions

- Thinking about return on investment means choosing a software editor and an integrator who understand the business and not the underlying IT. They must understand the customers needs and incorporate them in the future PLM solution.

Addressing the new challenges surrounding the digitalization of industry processes

Designing, prototyping, qualifying, manufacturing, quality control, maintaining, selling, recycling… and then start all over again. So goes the traditional life cycle of products.

In reality, companies often simply only connect the product design to technical data management, the backbone of a PLM project.

The new challenges of business digital transformation and the ever evolving technological environments are now changing the scope of action of the PLM project manager.

The time when a product was a mechanical assembly with some electronics is over. Today, each product is a complex mechatronical system combined with mechanical parts, electromechatronical components, electronics, hardware and software running together. All of this must be reconciled and the notion of the digital twins now becomes obvious. How to manage information of such complexity? What models to use? How to make the system capable to control and share the correct information? A lot of questions to which the PLM will have to answer.

The ways of designing these products and their processes, as well as their manufacturing methods are also impacted by the fast growing disruptive technologies (artificial intelligence, virtual reality, 3D printing, additive manufacturing, connected objects) as well as the growing importance and society concerns regarding environmental constraints and durable development.

The digital twin of these products must be able to simulate everything that can happen with the product in real life.

The interoperability capability of the PLM solution with the other industrial application landscape (ERP, MES), which is usually a weak link in projects, must also be strengthened by becoming part of a global MDM approach (Master Data Management, when product data is shared in an enterprise among multiple systems, with the same meaning and shared common values)

In the meantime solutions-related technology also evolves with Cloud, Saas, Big data …

The PLM project manager must be able to integrate all these sources of change and if necessary, to reconsider the content and organisation of the traditional steps of a PLM project in order to be able to support the business in its search for faster operational efficiency through digital transformation.

In conclusion

The PLM Project Manager is now involved in an environment of increasing complexity.

The now widespread concept of industry 4.0 or industry of the future foresees a new way of organising design and manufacturing. This new industry is proving to be the convergence of the virtual world, digital design, management with real world products and objects.

In this context a PLM project more than ever includes a strategic dimension, since traditional issues of IT development are added to the new issues of global optimisation and deep overhaul of the industry with a stated aim of improved performance, growth or simply survival.

The PLM project manager must now be a point of contact at the same time with a fine expertise in deploying PLM solutions, an excellent knowledge of the industrial sector in which he intervenes, and a sensitivity to extremely fast changes in his work environment.

The PLM project manager becomes therefore a strategic player in digital transformation.

Author: Christian GENEZ, Inensia PLM/MES Senior Project Manager