- Consider the specific mindset of Analysis & Simulation engineers

SPDM key users are necessarily “experimentation-minded” not so familiar with pre-defined processes guidance. They like to create new methods to get expected results. Start simple by tracking their activity in the system (steps, tools, results), you will get first SPDM value. Then implement first process automation on specific cases (simple simulation processes often used) and deploy progressively. Always keep simple ways to exit predefined processes and follow new steps. In addition, keep in mind they are often good programmers, so they can (even should) be deeply involved in SPDM technical implementation.

- Work with open and flexible technologies

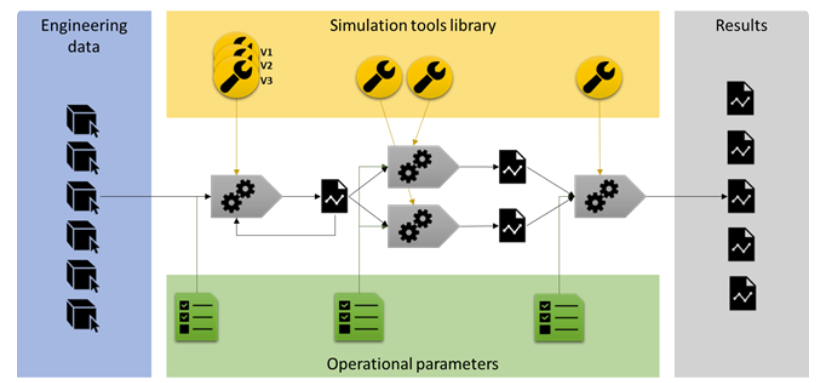

By necessity, Analysis and Simulation is an open activity, working with various software bricks coming from hundreds of vendors. The first characteristic of your SPDM technology must be openness, and ability to connect to any kind of software and data. Run away from vendors promising an integrated suite of internal tools to handle any situation…

Flexibility is also key, do not consider your simulation process as a pre-defined workflow (such as standard workflows of DM or PLM technologies), but as a flexible process, built step after step by the engineer. You can provide templates, but users should be able to escape it at any time.

- Do not underestimate the project preparation phase

Before implementing any information system, do a detailed cartography of your Analysis & Simulation activity: Type and volume of A&S requests, Software tools with versions and input/output specification, data & files location. Identify early in the project the critical parameters you want to follow for each type of request, they will become special metadata in the future system. Start capturing legacy data & files in a structured way for “first priority” simulation areas, this will be very helpful later in the SPDM project design phase, especially for the critical “legacy data migration” phase.

- Make your SPDM project agile

Nowadays, agility is extending to all IT domains, including implementation of large collaboration systems. Implementing SPDM in an agile way is very efficient to handle the high level of complexity, it would be almost impossible to do a complete initial specification of a simulation process. After an initial phase of business needs analysis (user stories) and solution architecture, a new version of the SPDM system is delivered every 2/3 weeks, so business representative can perform continuous testing and propose improvements. For deployment, start small on a first scope (couple of request types and embedded tools), use this pilot as support for communication and change management, then go to larger roll-out.

[*] Simulation Process and Data Management is an information system to support the Analysis and Simulation processes in industry. It covers management of A&S requests, process steps and input/output information, as well as steering of the different calculation software used throughout the process, so that all stakeholders can collaborate around a single view of A&S information.

Author: Sébastien GRAU, Inensia Co-Founder